Why should a FMEA not be represented as a spreadsheet structure?

|

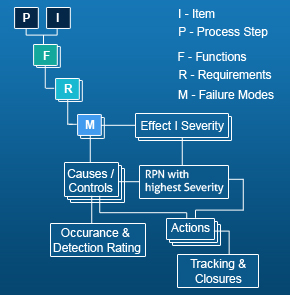

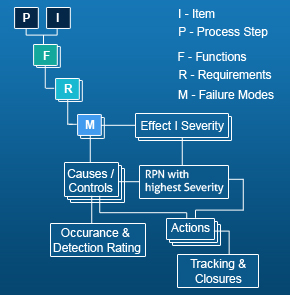

The structure representing a potential failure mode, its effects and causes is shown in the example.

As can be seen, a failure is not caused by a single cause. It can be caused by any one or multiple of the potential causes.

A failure once occurs will potentially lead to all the Effects listed here. No matter which cause has led to the failure.

Thus, there is direct one-to-one relationship between Causes and Effects.

A spreadsheet representation of FMEA leads to a mistaken belief that a Cause is related to an Effect written in the same row of the spreadsheet.

The actions for risk avoidance that stem out of such a belief will not be effective towards problem solving.

The true relationship in a FMEA is:

- Multiple Causes lead to a Failure Mode

- A Failure Mode leads to Multiple Effects

- Actions are required to be taken on Causes

This action oriented structure cannot be represented clearly in a spreadsheet. Spreadsheet can only be a status report on FMEA.

FMEA Executive correctly maintains FMEAs in a tree structure. Reports on the status of a FMEA can be generated in the spreadsheet structure on demand, at a click of the mouse.

|

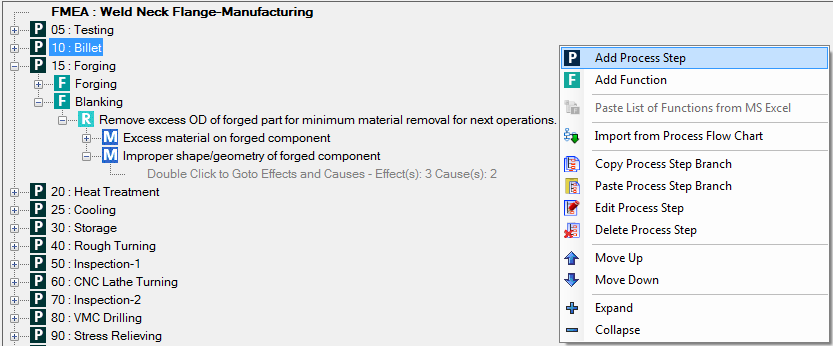

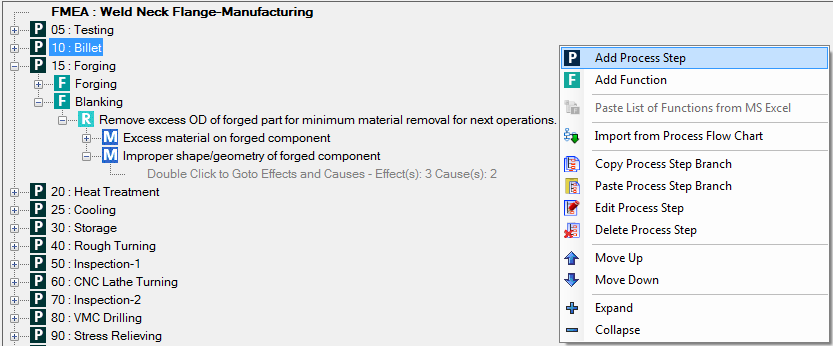

FMEA represented as a Tree Structure

|

FMEA Tree structure implemented in FMEA Executive showing

(P)rocess, (F)unction, (R)equirement & Failure (M)ode with context-sensitive pop-up menu

|

How does FMEA Executive help you choose a Severity Ranking?

|

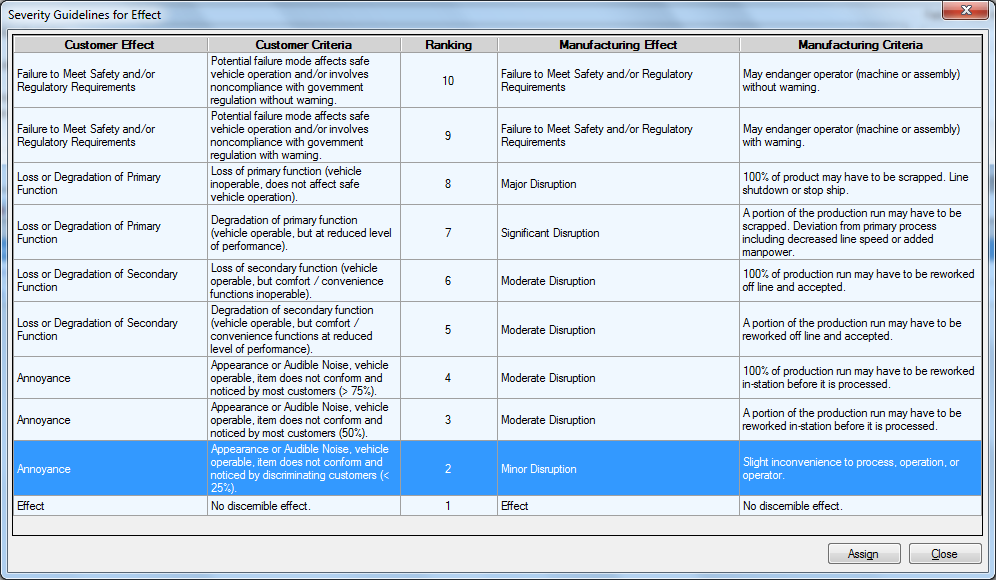

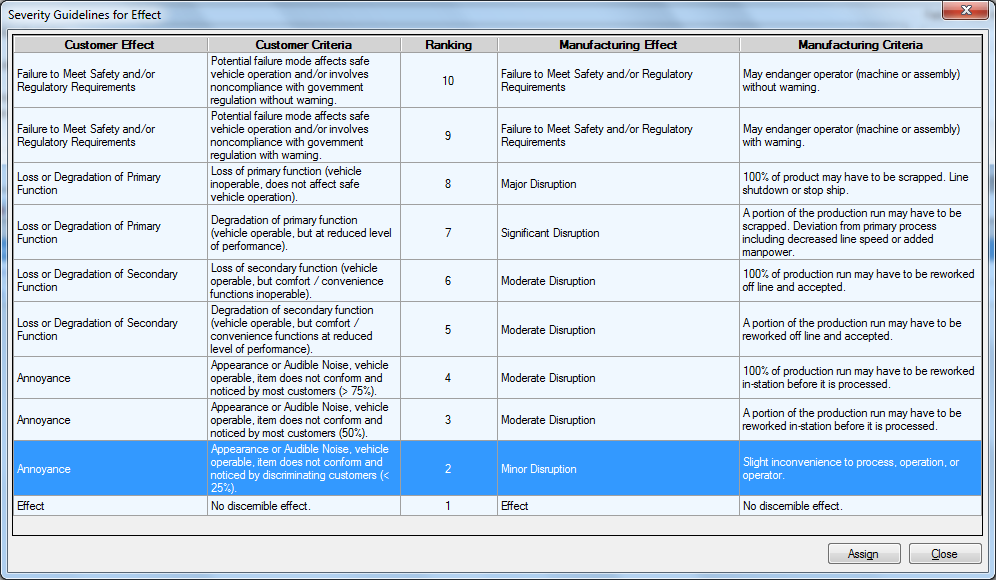

As often seen, team members may differ on their view on the Severity ranking to be assigned to an Effect of failure.

FMEA Executive has an on-line Severity ranking guide that helps the team correctly evaluate the Severity ranking and state the risk.

The screen shot here shows the Severity Ranking Guidelines incorporated in FMEA Executive software.

|

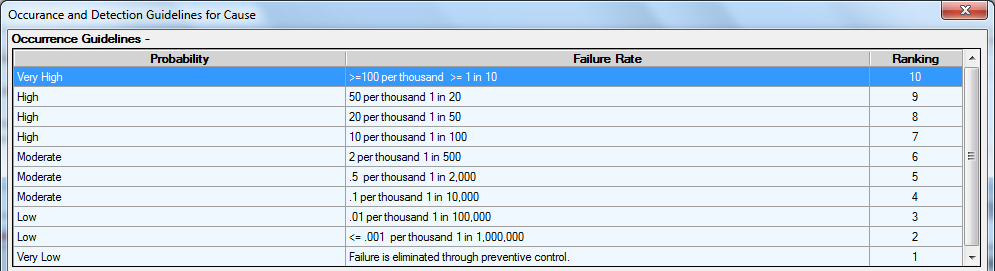

How does FMEA Executive help you choose an Occurrence Ranking?

|

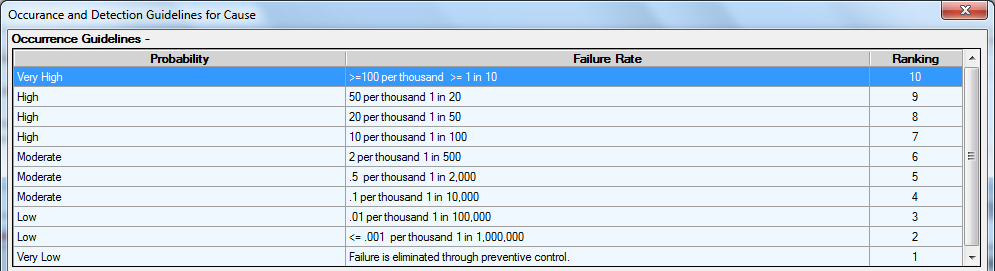

The team may differ on number of times the cause leading to failure may occur.

The Occurrence ranking to be assigned to a Cause is therefore subject to analysts' perception.

FMEA Executive has an on-line Occurrence ranking guide that helps the team correctly evaluate the Occurrence ranking and prioritize the risk.

The screen shot on the right shows the Occurrence Ranking Guidelines incorporated in FMEA Executive software.

|

|

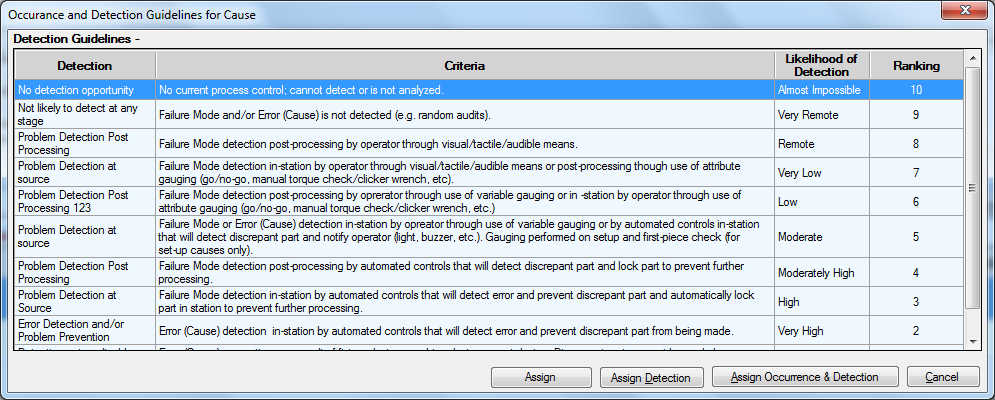

How does FMEA Executive help you choose a Detection Ranking?

|

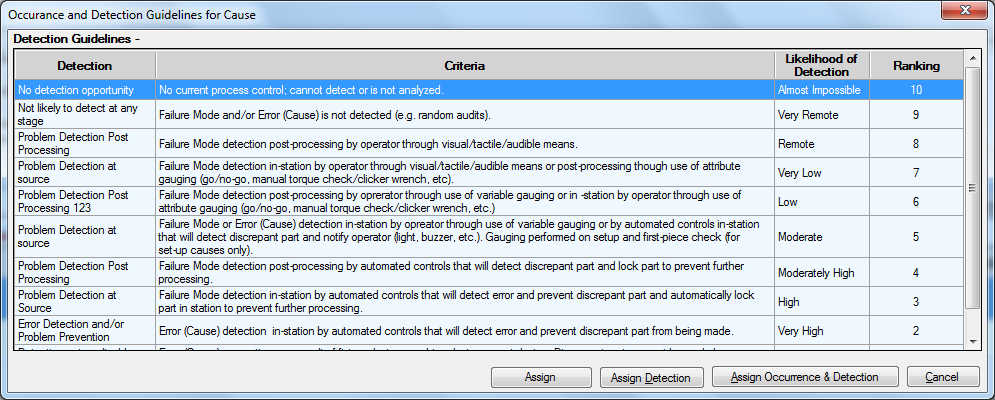

Based on the Current Controls of Detection, the team needs to assign a Detection ranking to the Cause leading to the Failure Mode.

There can be differences in the members' view on the correct Ranking to be assigned.

FMEA Executive has an on-line Detection ranking guide that helps the team correctly assign the Detection ranking and act on better controls to move towards prevention where this ranking is high.

The screen shot on the right shows the Detection Ranking Guidelines incorporated in FMEA Executive software.

|

|

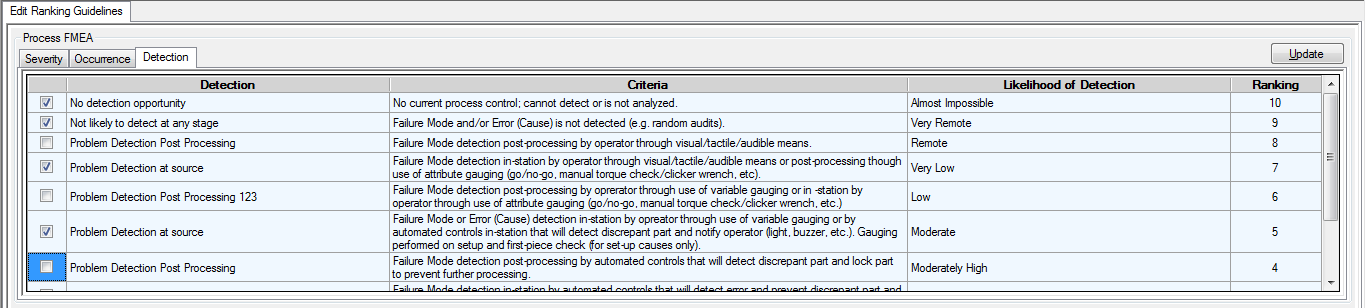

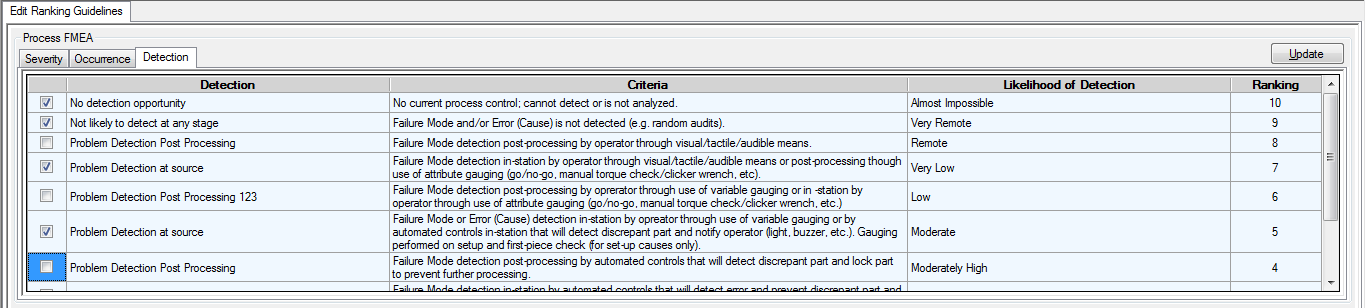

Can I customize my ranking guidelines?

Your organization Designs and Processes your unique product or service. Your DFMEA and PFMEA will therefore need to be aligned to the risk perception of your products rather than the standard guidelines given by a standard.

FMEA Executive gives you the facility to customize the Severity, Occurrence and Detection guidelines to best suit your Designs and Processes. Such customized guidelines are then available on-line to all the analysts who participate in the FMEA process. The evaluation of the Risk is therefore more accurate and uniform across the organization.

|

- Severity Rankings: You can change the descriptions in Effect and Criteria columns. These can be edited to include more relevant text for better understanding by the team members.

- Occurrence Rankings: You can change the Probability, Failure Rate, Likelihood and other criteria to better suit your products and services based on your past experiences. This would help team members arrive at a consensus.

- Detection Rankings: You can change the descriptions in Detection, Criteria and Likelihood columns.

- Better Resolution: Although overall rankings remain on a scale of 1 to 10, you can choose to omit certain rankings to bring about a better resolution in ranking numbers. For example, you may only allow ranking on a scale of 1,3,5,7,9 and 10 and disallow use of other rankings.

What are the supervisory controls in accessing FMEAs?

It is essential that the vast knowledge base contained in the FMEA database be used by all analysts addressing FMEA. The privilege of updating every FMEA however, needs to lie with persons responsible for that FMEA.

FMEA Executive enables the following roles for each member who has a valid login to the system:

| Default Role (User) |

Anyone who has an authorized login will be able to view and search all FMEAs in the system. |

| FMEA Owner |

Any person can be designated as an owner to FMEAs. A single FMEA can have multiple owners. |

| FMEA Core Team Member |

Persons related to an FMEA can be designated as a Core Team Member to FMEAs they are participating in. |

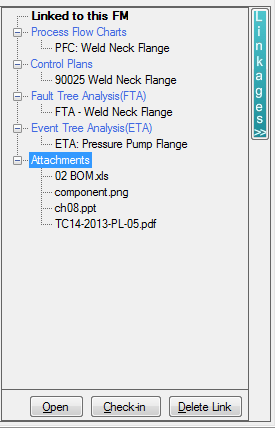

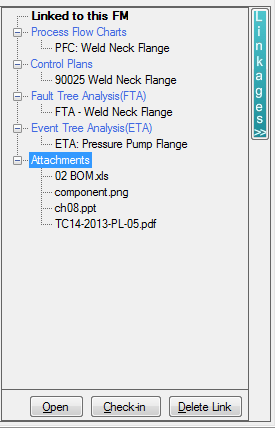

I want to reference external documents to FMEAs

|

External documents that contain source information to Failure Analysis are vital for reference and result oriented actions.

FMEA Executive gives you a choice to check-in a wide variety of external documents into the FMEA data repository. Check in Failure reports in MS Word format, test data as spreadsheets, pictures of failed components, scanned documents containing standard operating procedures and a wealth of other information that needs to go with FMEA.

Any MS Windows readable format document can be checked-in and referred to be all, so long the program opening the document is installed on the computer you use.

External documents can be attached to FMEAs or also to individual Failure Modes.

Such vast expanse of information that is available at a click of the mouse enables you appreciate, act upon and solve a problem speedily.

|

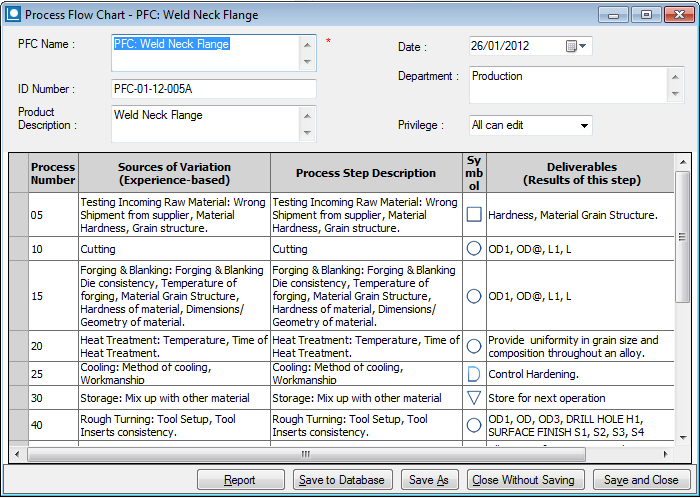

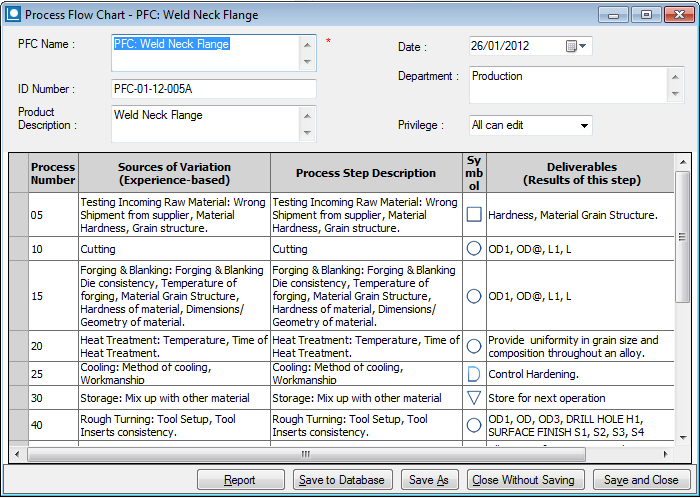

How does a Process Flow Diagram work with a Process FMEA?

|

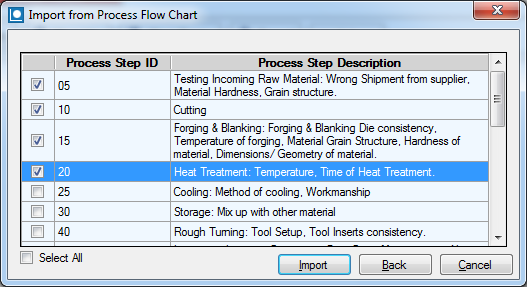

It is a good practice to create a Process Flow Diagram before embarking upon a Process FMEA.

FMEA Executive has a facility of creating Process Flow Diagrams. The Process Steps in the Process Flow Diagram are linked to the Process Steps in a related FMEA through the Process Step number. The Process Step Number therefore becomes vital as a link between the Process Flow Diagram and the FMEA.

A Process Flow Diagram enumerates the Process Steps in the process under study. The Process Flow diagram identifies the sources of variation in each Process Step. The Process Flow Diagram also lists the Deliverables from each Process Step. The deliverables from each process step lead to the Requirements of functions for that Process Step. A clear description of Requirements in a FMEA then lead to the identification of Failure Modes in a FMEA.

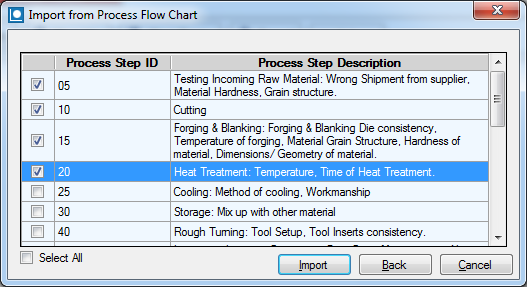

FMEA Executive gives you a facility to select and import Process Steps from a pre-defined Process Flow Diagram into a PFMEA.

|

How does a Control Plan work with PFMEA?

|

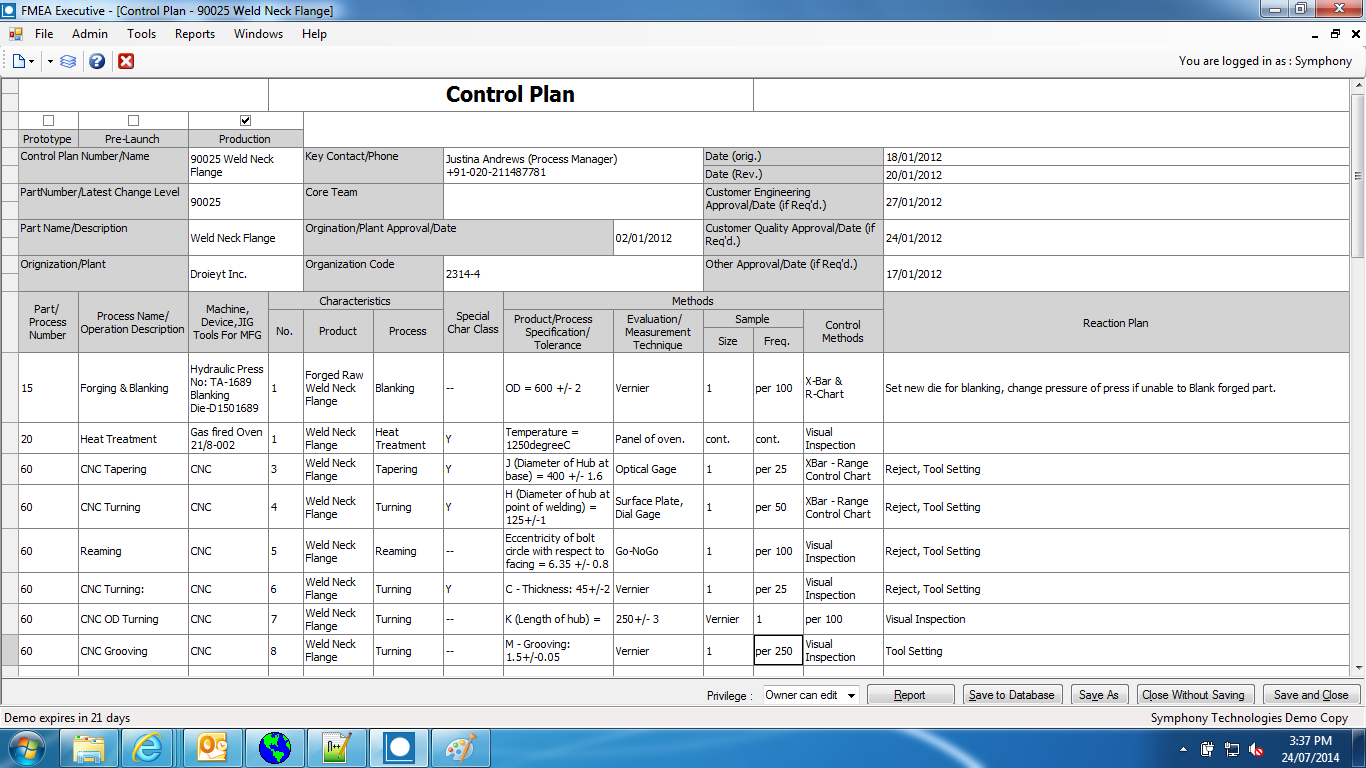

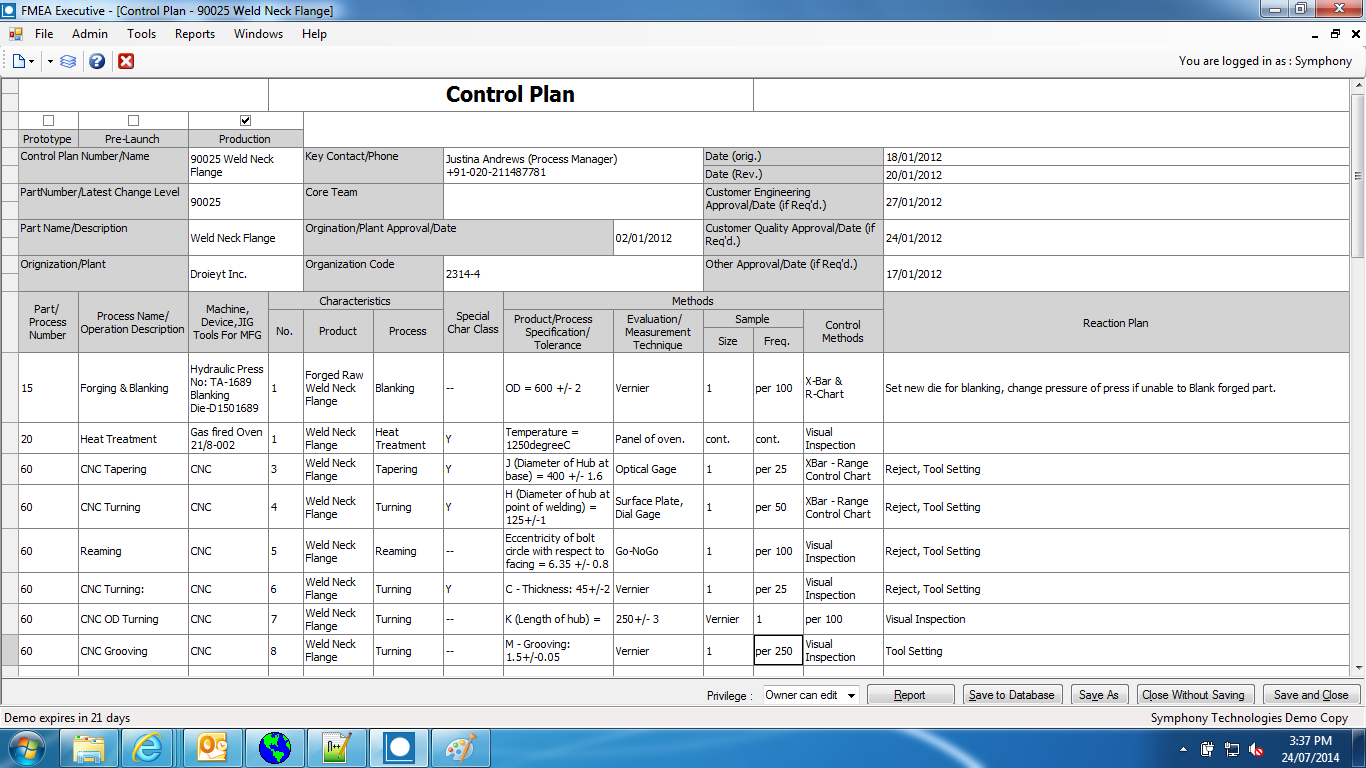

A Control Plan is an action plan to mitigate the failure risks identified in a PFMEA.

The Process Steps in the PFMEA are linked to the Process Steps in a related Control Plan through the Process Step number. The Process Step Number should therefore be consistent across PFMEAs and Control Plans.

FMEA Executive gives you a facility to create Control Plans.

A Control Plan is a plan to control Product and Process characteristics. It documents what needs to be measured and controlled and how the control needs to be put in place in the process.

The screen shows Control Plan implementation in FMEA Executive software.

|

How does a P-Diagram work with a DFMEA?

|

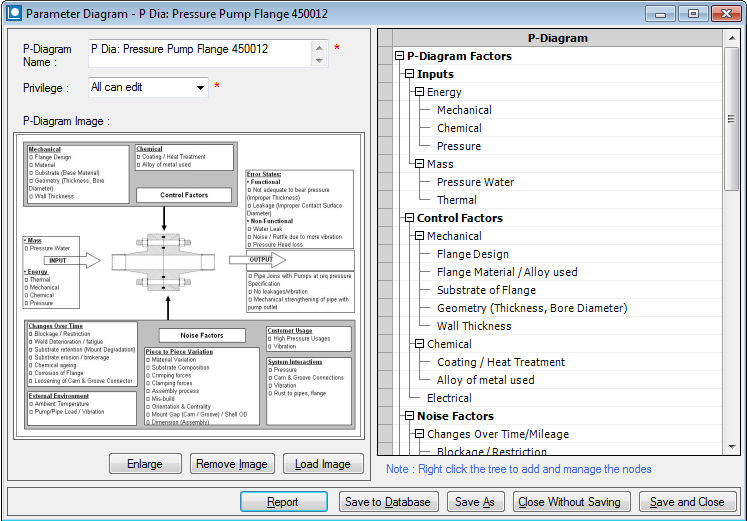

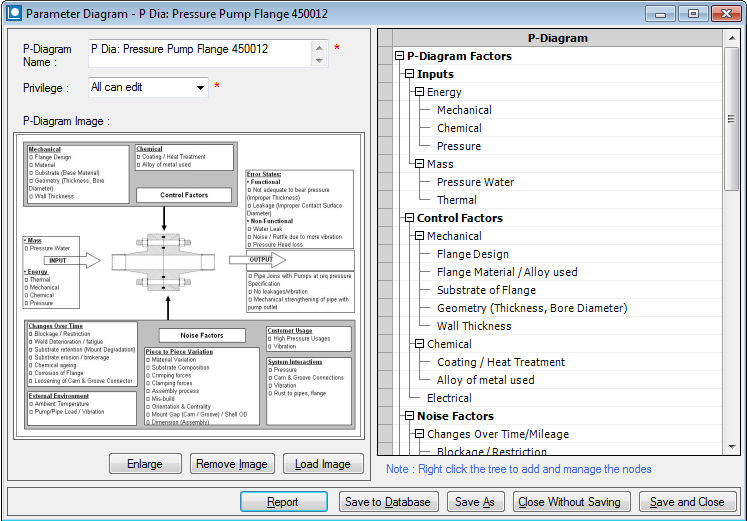

A P-Diagram ( Parameter Diagram) is a description of the functioning of the system under design. FMEA Executive has a built-in facility to create P Diagrams.

A P-Diagram defines the following:

- Signal and Responses: A Signal is an input to the system under design and the Responses are the Outputs from the system as expected by the design. Signal and Responses enable you visualize the functioning of the system.

- Error States: These are the undesirable outcomes when the system converts the Signals to Responses. Understanding Error States lead you to identification of Failure Modes.

- Control Factors: These are the design features you have built into the system to facilitate its functioning. Control Factors help you in identifying the current controls in a system that help preventing potential causes of failure.

- Noise Factors: Noise factors are variations in the environment in which the system needs to function. While working on a FMEA, the analyst needs to seek means by which the system functioning can be made robust to Noise Factors. Failures that arise due to variations in product or system usage can thus be prevented.

A P-Diagram is an excellent visualization of the system functioning and environment that can pinpoint potential for failure effectively.

The screen shows how FMEA Executive software implements a P-Diagram.

|

|

How can Fault Tree Analysis and Event Tree Analysis help in a FMEA?

|

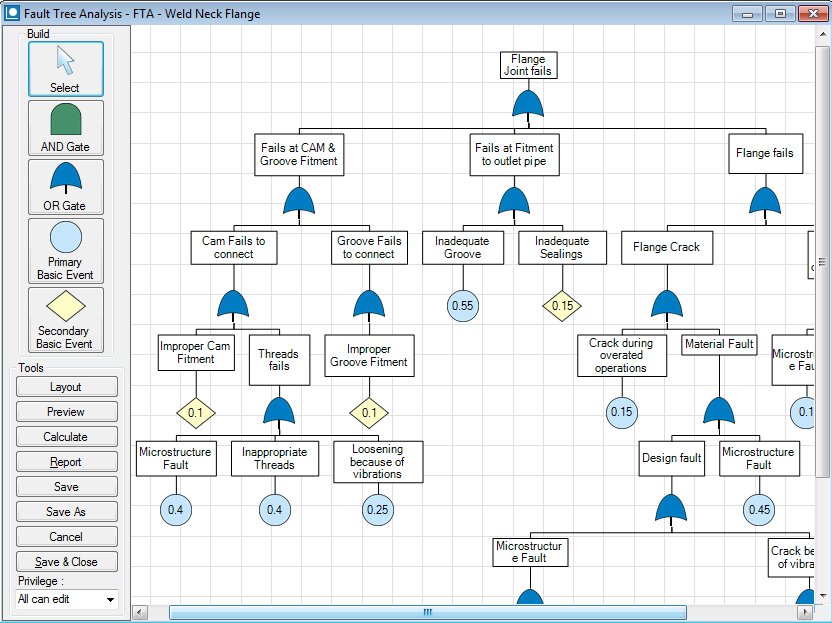

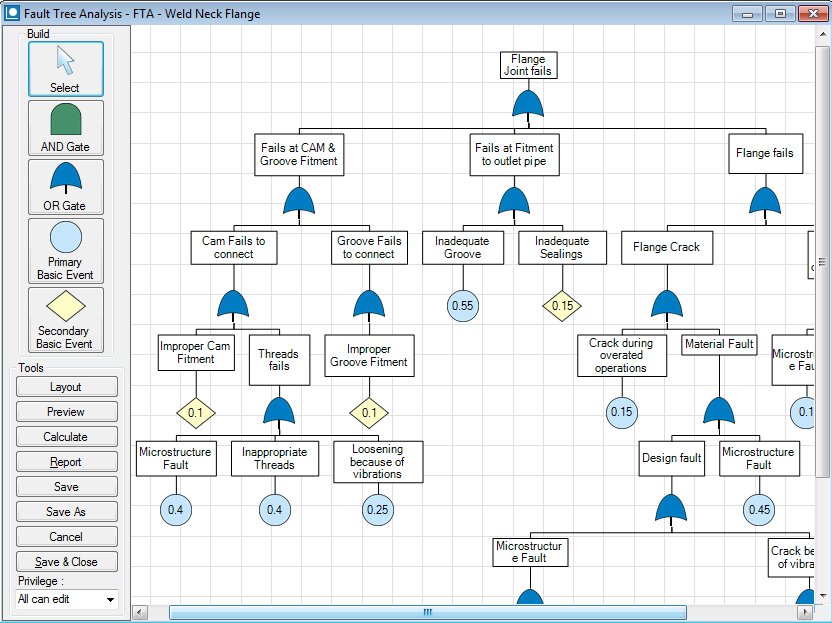

Systems often are an integration of sub-systems. Sub-systems are integrated together through a specific functional structure.

-

A Fault Tree is a representation of such functional integrated structure of sub-systems. A failure in a sub-system can potentially lead to the failure of the entire system. A fault tree will evaluate areas of high risk in failures and help you calculate the probabilities of system failure based on the probabilities of sub-system failure.

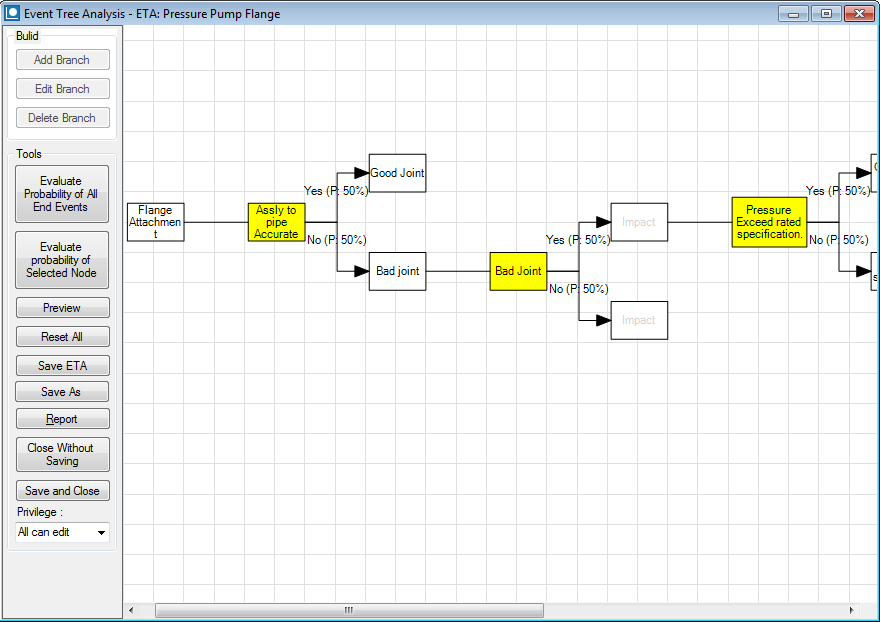

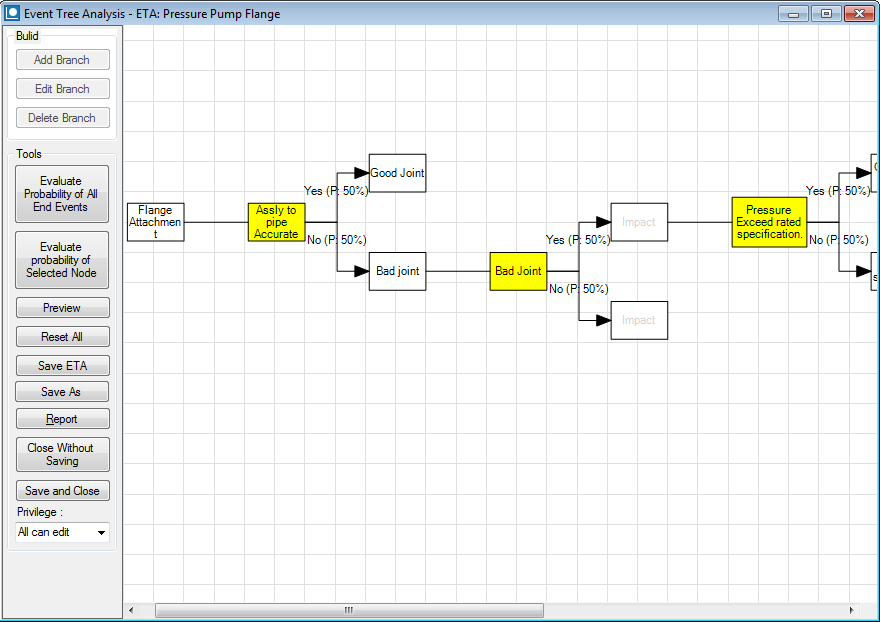

- An Event Tree models sequential-event led failures in systems. Each node in the Event tree logs the possibility of the event occurring. Based on complex chains of sequenced failures, high risk events are highlighted. Adding redundancies and reducing probability of critical events will help bringing down the Failure rate in a significant manner.

FMEA Executive has a built in facility of building and analyzing Fault Trees as well as Event Trees.

|

Fault Tree Analysis Module in FMEA Executive software

|

Event Tree Analysis Module in FMEA Executive software

|

How do System, Subsystem and Component FMEAs connect together?

There is often a need to bind Component, Sub-system and System FMEAs together and maintain them in coherence with each other.

FMEA Executive offers a feature of soft-attach, that helps you insert selected Items / Process steps of a FMEA into another.

You can create the sub-system FMEAs independently, and soft-attach them into the System FMEA. Any updates made at the Sub-system / component level will reflect into all the system FMEAs in which the component / sub-system FMEA is soft-attached. This happens in real time without a delay.

This way component, sub-system and system FMEAs can be maintained in a tight integration with each other.

Can I reference sections of other FMEAs and maintain integrity of changes?

FMEA Executive offers a feature of soft-attach, that helps you insert selected Items / Process steps of a FMEA into another.

You can create the sub-system FMEAs independently, and soft-attach them into the System FMEA. Any updates made at the Sub-system / component level will reflect into all the system FMEAs in which the component / sub-system FMEA is soft-attached. This happens in real time without a delay.

This way component, sub-system and system FMEAs can be maintained in a tight integration with each other.

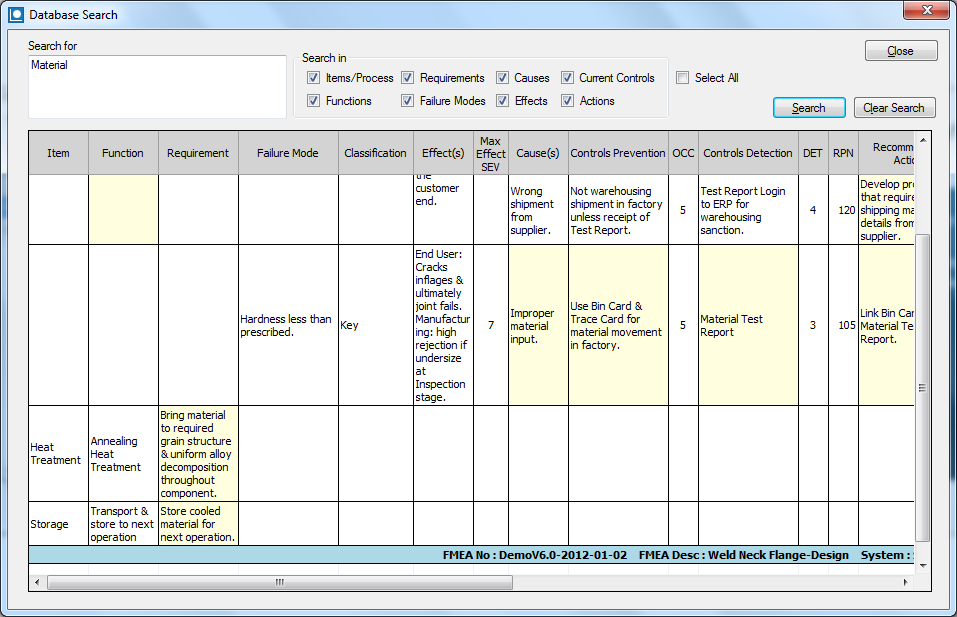

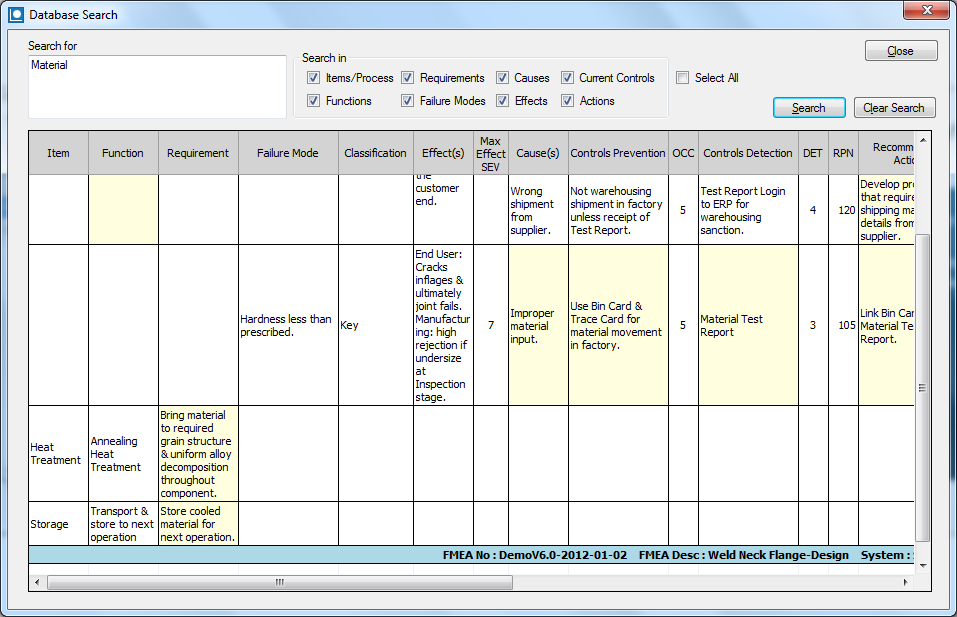

How do I search the existing Knowledge Base in the FMEAs I have already created?

|

FMEA Executive can maintain all your FMEAs in a common server-based database. Information about Items, Process Steps, Functions, Requirements, Failure Modes, Causes and Effects as well as the information of successful actions in the past are logged into this database.

FMEA Executive gives you a search facility by which you can swiftly do a structured keyword search on the entire database. Failure Modes worked upon in the past, actions that have worked as well as those that have not worked, high risk potential areas and the entire knowledge-base on FMEA is now at hand.

This will enable you build upon the experiences and work done in the past. Learning from the past will make your problem solving cycle short in duration and effective in outcome.

The search facility is available to the FMEA team throughout the workflow FMEA Executive software offers.

|

|

How do I assign and track actions to be taken?

FMEA Executive given you action oriented reports on demand. View with a click of the mouse, all the actions overdue for you and actions coming up in an immediate future horizon. Actions can be prioritized based on the Severity rankings and the Risk Priority Number.

FMEA Executive has a facility of sending an email notification to all concerned analysts as soon as any action has been assigned to them.

How do I prioritize actions I need to take?

The sole use of Risk Priority Number as the means of prioritization can be misleading.

A better approach would be to prioritize in a two-step manner.

Address all the causes of Failure Modes where Highest Severity ranking is 10 or 9. 10 or 9 ranking refers to safety and such cases must be addressed first.

Once the 10 & 9 Severity cases are dealt with, the rest can be based on a descending order of RPN.

FMEA Executive gives a exception report that prioritizes on the basis shown above. FMEA Executive also generates a report that prioritizes the Failure Mode based on sum of RPNs due to all causes. High risk areas are thus highlighted and risk mitigation activities can be effectively focused upon.

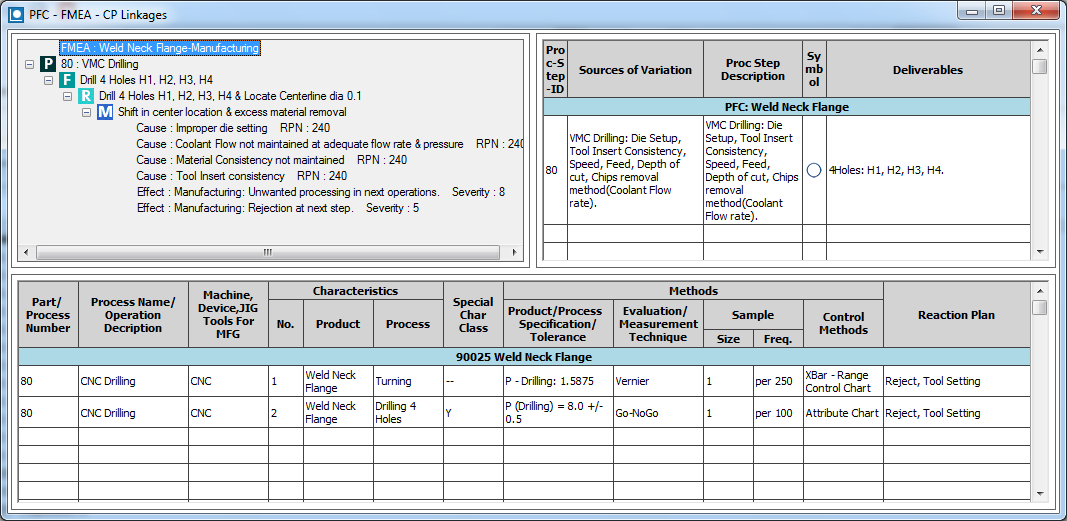

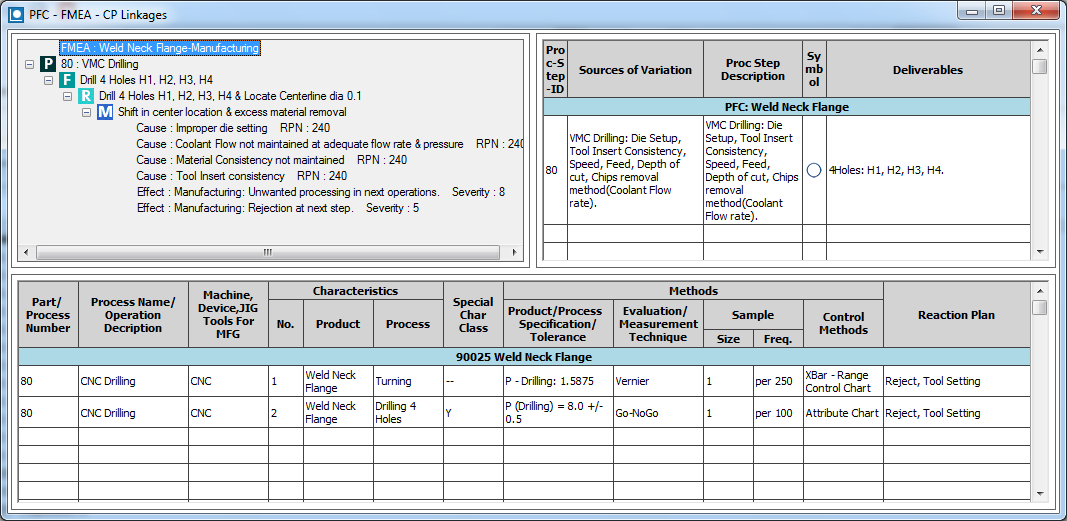

How do I effect linkages of Process Flow Chart-Process FMEA-Control Plan?

|

- A process flow chart identifies the where risk of potential failure can occur.

- A FMEA aims at mitigating the risk through systematic analysis.

- A Control Plan puts in place a system to control risk avoidance.

The Process Step Number is a common thread that binds the three together.

FMEA Executive gives you a facility to view the Process Flow Chart, FMEA and Control Plan for a selected Process Step in a single view.

|

|

How do I create generic FMEAs for family of products?

You could create a base FMEA that addresses common failures that similar products (a product family) are susceptible to.

Branches from such base FMEAs can be soft attached into specific product FMEAs as required. The specific product FMEA additionally can have its own branches too.

Any changes made to the base FMEA will reflect automatically in all FMEAs it is linked into.

How do I derive new FMEAs from existing ones?

FMEA Executive gives you a 'Save As' facility where existing FMEAs can be saved as new ones. Where it is necessary to maintain integrity between existing FMEAs and the derived ones, the soft-attach feature offered by FMEA Executive can be used.

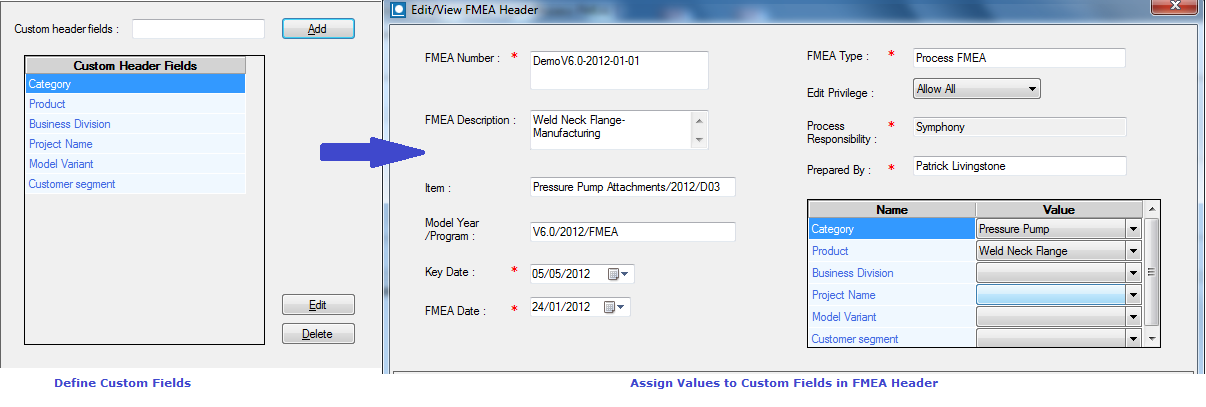

Can I add my own fields to a FMEA header?

Yes, you can create an unlimited number of custom fields in the FMEA header. Custom fields such as Project name, Model variant, Customer segment help you to classify, sort and search out FMEAs of specific interest.

Can I run FMEA Executive from a Server?

|

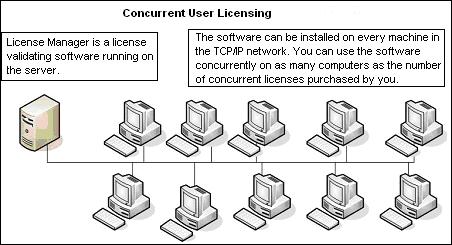

FMEA is a team activity, and is best supported by a network enabled software. FMEA Executive supports a network implementation.

Database Sharing: The FMEA database resides on a server from where it can be accessible by all computers that run the FMEA Executive software. FMEA Executive software has built in data locking and concurrency control to ensure the integrity of data. The knowledge that resides in a common FMEA repository is thus available across the network for an effective FMEA implementation.

Concurrent Licensing: We also offer Server-based concurrent user licensing for FMEA Executive software. The basic scheme is shown here.

Write to us for the various licensing options offered for FMEA Executive software.

Write to us for the various licensing options offered for FMEA Executive software.

|

|

Can you offer us a custom FMEA solution based on our specifications?

SymphonyTech offerings include custom as well as standard software

We have a deep expertise in analytics related to Quality, Engineering and Manufacturing. This expertise has been brought home to our distinguished customers around the world through standard and custom software .

We can work with you to design, develop and implement effective solutions in our area of expertise. Please write to us for your requirements of MS Windows based as well as web based software solutions. Trust us to bring you the best.

For more info, visit our Custom Software page.

For more info, visit our Custom Software page.

sign below to expand the answer.

sign below to expand the answer.

If you have any query, just

If you have any query, just