This short article is aimed at providing a quick insight into how to use the FMEA method to make FMEA easier to practice and deliver better results. We shall look at Process FMEA based on the AIAG-VDA Harmonized handbook.

Failure Mode & Effects Analysis has been identified as one of the most effective methods of Failure Prevention.

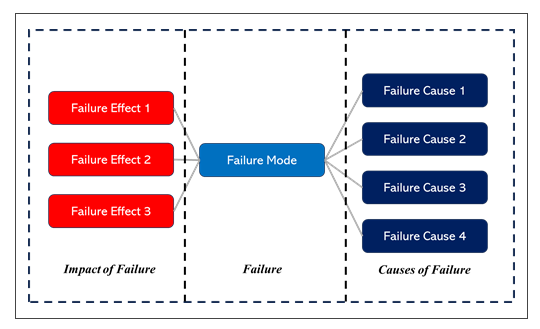

Let us define three terms that we have been using in FMEA

- Failure Mode: Definition of Failure. What is going wrong?

- Failure Effects: Adverse Effects of Failure described in Failure Mode. There will be multiple adverse Effects of every Failure.

- Failure Causes: Reasons for Failure. There will be multiple Causes leading to a Failure Mode.

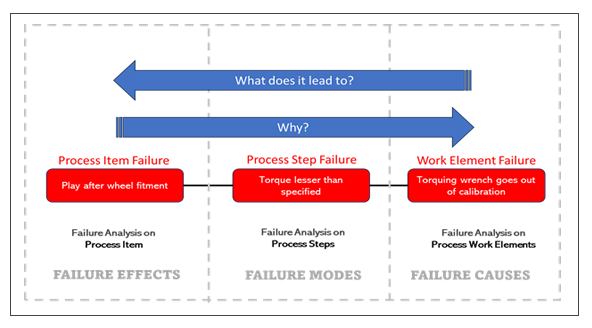

The diagram shown below makes it easy to visualize the relationships.

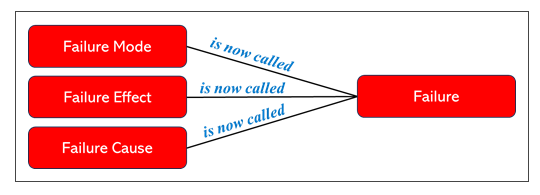

The AIAG-VDA FMEA method makes everything very easy.

Instead of getting lost in the maze of Failure Modes, Failure Effects and Failure Causes we do Failure analysis using a single term ‘Failure’.

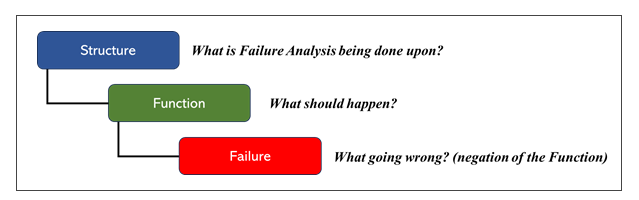

The workflow of analysis too is a simple three step process shown here:

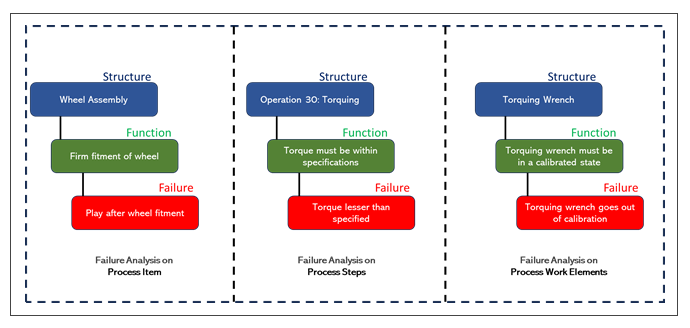

In Process FMEA this Structure-Function- Failure relationships repeat themselves in three places. The following example illustrates these relationships.

As can be seen in the example, Failure Analysis is done using the Structure-Function-Failure relationships for the following type of Structures:

- Process Item: Product upon which the Process is being done.

- Process Steps: Each step through which the Process is performed.

- Process Work Elements: Accessories, Toolings, Attachments and Auxiliaries that are used to perform each process step. These are typically Man/ Machine/ Material/ Method elements that go into a process.

Looking at the example again, we see the Why and What relationships relating these different levels of failures.

Once we do Failure Analysis at Process Item, Process Step and Process Work Element level, all we need to understand is the following:

- Failures of Process Items are Failure Effects.

- Failures of Process Steps are Failure Modes.

- Failures of Work Elements are Failure Causes. You take actions here.

In your FMEA tabular format, all you need to do is to place these elements in their proper columns.

The Why and What relationships are called Failure Chains.

In Summary - Your Benefits

A clear understanding of Failures at different places makes our FMEA easy and effective due to the following reasons.

- We clearly know that we need to look for:

- Failure Modes in Process Steps.

- Failure Effects in Process Items.

- Failure Causes in Process Work Elements

- We do not confuse ourselves between Failure Modes, Causes and Effects.

- We know where to take actions.

- Once a Failure Mode is identified, we do not need to conjure up Effects and Causes from our imagination. They are sitting right there, clearly visible.

In summary, FMEA done with such a scientific approach makes it easy to perform and effective in its outcome.

|

Ravindra Khare |

FMEA Executive AIAG-VDA Edition software helps you perform Design and Process FMEA. The software complies to the methods stipulated of the AIAG-VDA Harmonized Edition Handbook for FMEA. You work on your FMEAs through an intuitive, graphical way that's easy to perform.

Thoughtfully designed features help you take your Design and Process FMEA efforts beyond mere documentation. Your FMEA initiatives become Effective and Result oriented.

Top

Top